How high performance butterfly valve Can Enhance Performance and Reliability in Industrial Processes

High-performance butterfly valve are specifically designed to enhance performance and reliability in industrial processes. Here are the ways in which they can achieve these improvements:

Excellent Flow Control:

High-performance butterfly valves are engineered to provide precise flow control in industrial processes. Their design allows for efficient throttling and regulation of flow rates, ensuring optimal performance and productivity. The streamlined disc design and low-pressure drop characteristics of these valves minimize flow turbulence, resulting in improved efficiency and reduced energy consumption.

Quick and Responsive Operation:

High-performance butterfly valves offer fast and responsive operation. They can quickly open or close, allowing for immediate adjustments to flow rates or shut-off requirements. This rapid response time is essential in industrial processes where time-sensitive control is necessary, such as in batch operations or emergency shutdown scenarios.

High Pressure and Temperature Capability:

These valves are designed to handle high-pressure and high-temperature applications commonly found in industrial processes. They are constructed from robust materials such as stainless steel, duplex steel, or high-nickel alloys, which provide excellent strength and resistance to corrosion, erosion, and thermal stress. This capability ensures reliable performance and longevity even in demanding operating conditions.

Bubble-Tight Shut-Off:

High-performance butterfly valves are designed to achieve bubble-tight shut-off, meaning they can seal tightly and prevent any leakage in both flow directions. This feature is crucial in industrial processes where precise control over fluid flow and prevention of leaks are essential for safety and environmental compliance.

Tight Control and Throttling:

High-performance butterfly valves offer precise control and throttling capabilities. Their design allows for accurate positioning of the disc, enabling fine adjustments to flow rates and precise control over process variables. This level of control enhances process efficiency, accuracy, and consistency.

Versatility and Adaptability:

High-performance butterfly valves are versatile and can be used in a wide range of industrial applications. They are suitable for various fluids, including gases, liquids, and slurries. Their adaptability makes them a preferred choice in industries such as chemical processing, oil and gas, power generation, water treatment, and HVAC systems.

Low Maintenance Requirements:

High-performance butterfly valves are designed for minimal maintenance needs. The streamlined design with fewer moving parts reduces the risk of wear and tear, minimizing the need for frequent maintenance or replacement. This characteristic contributes to increased uptime and reduced maintenance costs in industrial processes.

System Integration and Automation:

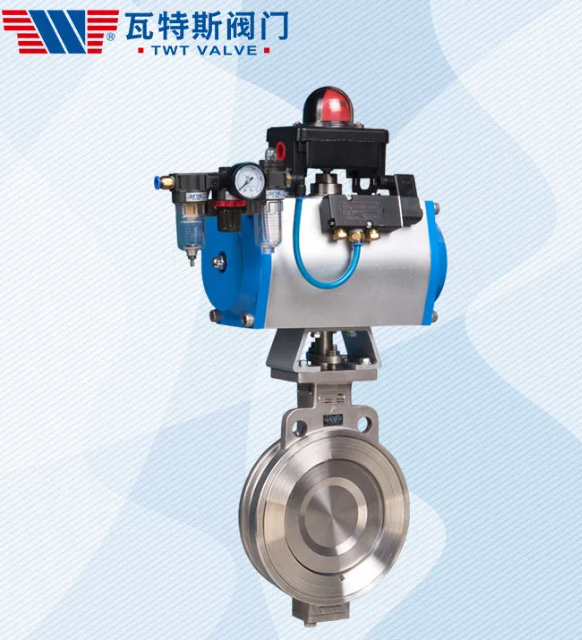

High-performance butterfly valves can be easily integrated into control systems and automated processes. They can be equipped with actuators and positioners to enable remote operation and integration with centralized control systems. This integration enhances process efficiency, reduces manual intervention, and allows for seamless integration with other process equipment.

In summary, high-performance butterfly valves enhance performance and reliability in industrial processes through excellent flow control, quick and responsive operation, high-pressure and temperature capability, bubble-tight shut-off, tight control and throttling, versatility, low maintenance requirements, and system integration capabilities. These valves provide reliable and efficient flow control solutions, contributing to improved process efficiency, productivity, and safety.